Plastic

Light and hard-wearing PET (polyethylene terephthalate) plastic bottles make excellent protective barriers for the water they contain. Having become items we take with us as we go about our days, they are now the subject of debate because they are being found as litter in nature. This is why we are committed to significantly reducing our plastic use and exploring new alternatives.

Less plastic

Towards less plastic in our bottles

We are aiming for this with all our bottle formats.

And less virgin plastic

We have also added recycled materials to our manufacturing processes.

> Recycled PET in our bottles: this material has the same properties as new PET, but has already had one life, then been put in the recycling, collected and turned into a new reusable plastic material.

Why recycled PET rather than virgin PET?

> And recycled material (PE) in our plastic film: we’re already using 50% for our for all our formats.

Working towards plastic alternatives

Our Packaging Science Institute is working on alternatives to plastic with eco-friendly packaging. Meanwhile, Nestlé Waters is a founding member of the NaturALL Bottle Alliance in partnership with Californian start-up Origin Materials, which is trying to develop 100% biosourced packaging solutions that come from sustainable and renewable sources, such as recycled cardboard and sawdust.

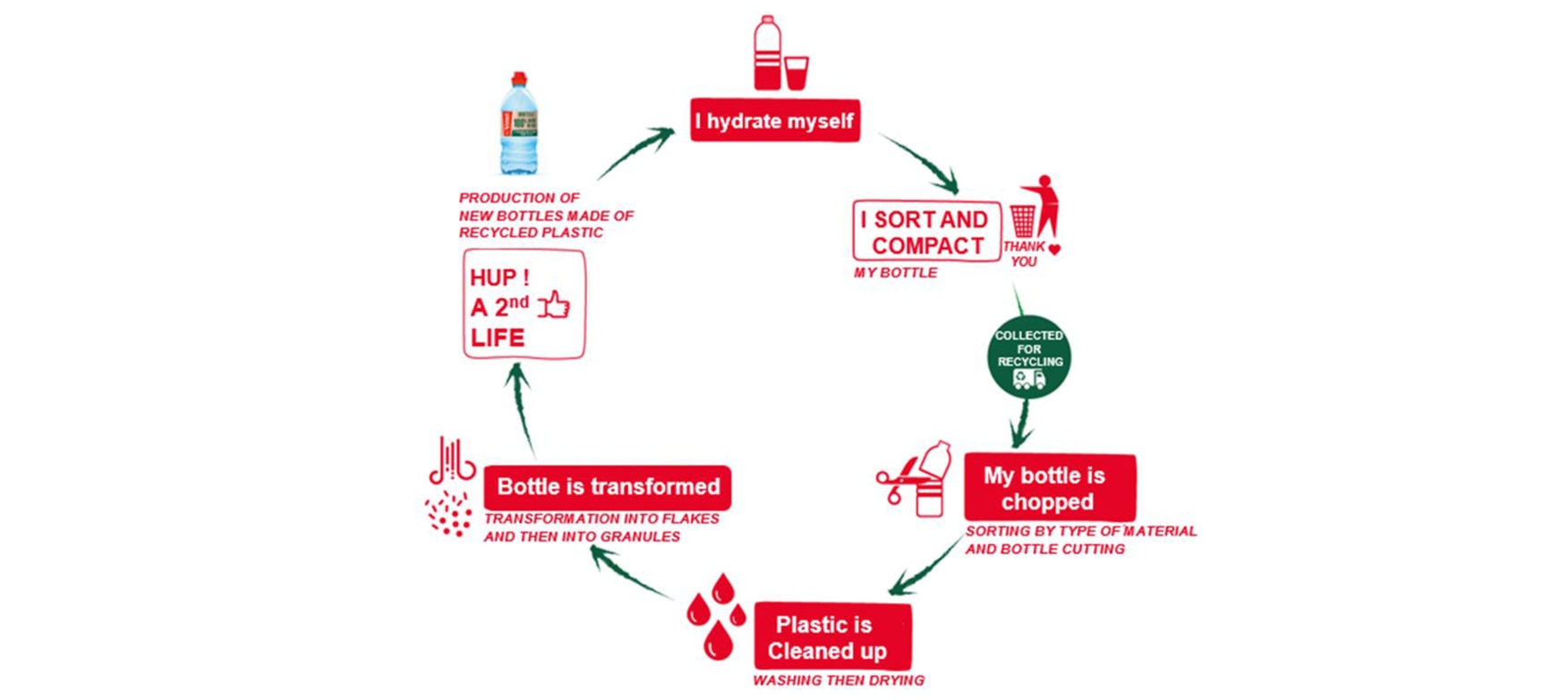

When a properly recycled bottle becomes a resource

Recycling has a real purpose. When plastic bottles are properly recycled, they become resources rather than rubbish. This means recycling and the circular economy are real solutions. Our bottles are all 100% recyclable (bottle and cap included, to be entirely thrown in the recycling bin), whether they contain virgin or recycled PET! When properly sorted and recycled, they can be used to manufacture new bottles, thus limiting the use of fossil fuels and CO2 emissions.

By March 2021, 100% of Vittel plain range will be made in rPET. All our small formats and the 2L already contain 100% !

Our objective by 2030 ? To have as many recycled plastic bottles as there are bottles produced by our Vittel® factory! And already 90% by 2025 !

This is why Vittel® is contributing financially through the Nestlé Waters Group to national recycling services in the main countries where the brand is sold, and is also a member of the New Plastics Economy (an initiative launched by the Ellen MacArthur Foundation and the United Nations). Finally, we are working with major international sports events which partner Vittel®, like the Paris Half Marathon and Marathon and the Tour de France, in a bid to have all the plastic bottles used by the athletes collected.

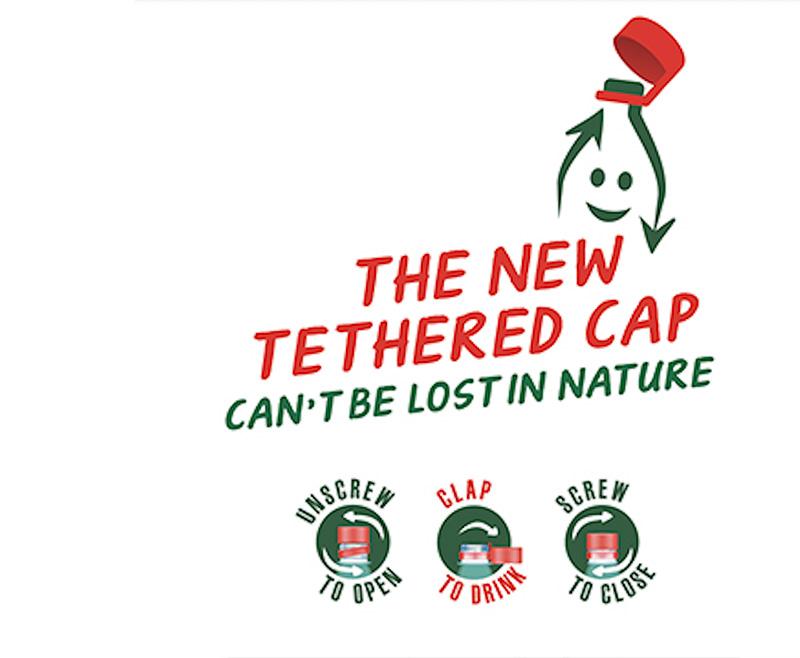

A tethered cap that does not get lost in nature!

Vittel® bottles are now equipped with a tethered cap that does not come off*. Just as airtight and resistant as the previous cap, the tethered cap is user-friendly. It can be unscrewed and screwed back on like the previous one, and above all, it is not lost in nature! This innovation is part of an approach that is more and more respectful of the environment in order to put an end to caps thrown away in nature.

* In accordance with the new European regulations.

Reducing our energy footprint

Less carbon

Between 2011 and 2016, our factory cut greenhouse gas emissions by 30% per litre of production.

Transport is a key aspect of any environmental strategy and in 2011 we signed an unprecedented partnership agreement with the SNCF to use the railway to transport our bottles. Today, over a third of Vittel® bottles are transported by train.

In 2017, Vittel® and the Nestlé Waters France Group became involved with FRET 21: a voluntary programme that helps reduce greenhouse gas emissions linked to freight. Various initiatives have been undertaken including more freight train wagons, investment in the first hybrid locomotive in France between the Vittel® factory and Arles, optimising journeys with more loops to limit empty runs, and natural gas lorries. By the end of 2019, these will have saved almost 500 tonnes of CO2 in three years when transporting Vittel® bottles: the amount produced by over three million miles in the car!

Less energy

Energy consumption is also one of our daily environmental battles. All the electricity used at our Vittel® bottling factory is renewable and French-origin. We have also cut our energy consumption by 14% for electricity and 9% for gas in four years by buying effective industrial tools and better managing our production processes. And we’re not stopping there! Our environmental energy transition will only be gaining momentum in the coming years.

Protecting the spring

Protecting the land means quality water: we’re all in this together!

*Water helps to maintain normal physical and cognitive functions. Drink at least two litres of water a day from any safe source.